Welded Plate Girder

The PLC offers the ability to quickly change parameters for different welding applications with ease, reliability, quality and versatility. Panel view screens can also be used to program the beam layout weld parameters for various beam sections.

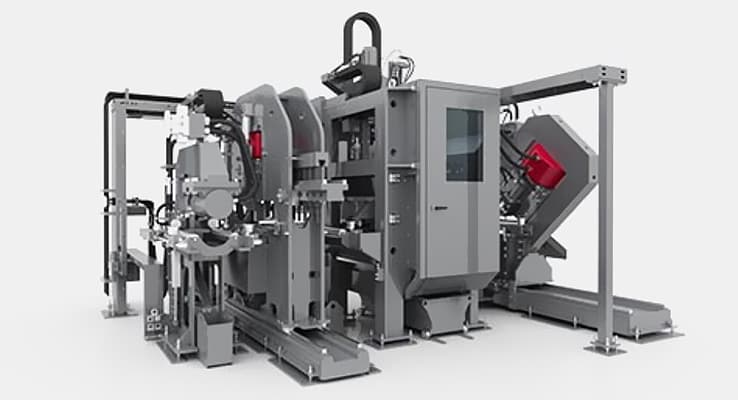

.jpg)